Engine out difficulties

Moderator: Board Moderators

-

chris knowles

- Senior Poster

- Posts: 426

- Joined: Thu Dec 29, 2005 16:26

Engine out difficulties

Hi Guys,

With my new Engine Hoist in place I spent the weekend trying to remove my engine, however....

I want to take just the engine out, and leave the gearbox in the car, as I don't think my hoist will lift high enough to remove both as a unit from the engine bay in one go. My issue is trying to split the engine and gearbox at the bell housing. I have removed all the bolts, and wobbled the whole assembly to try and get them to split, but no joy. I have even put a bit of wood through the hole where the starter motor sits and banged with a mallet against the back of the bell housing.....

All this leads to me being stuck with the engine dangling from the hoist, and the gearbox refusing to come loose, and a big canvas covering the lot from the rain until I know what to do. The car had sat for several years before I have started to work on it, what are the chances it has rusted together a bit? What is the cure?

So, in brief:

1) Anyone else had this problem, and found a way round?

2) What about lifting the body off the chassis and away from the engine, making access easier? The body is a completely stripped shell with everything removed, and the 12 chassis to body bolts gone too. Can this be lifted with 4 blokes, (the glass is still in)?

I read a post on here about removing the engine being a three minute job, no such luck! If only I had an over-head beam so that I could use a block and tackle, then lifting height would be no issue.....

Chris

With my new Engine Hoist in place I spent the weekend trying to remove my engine, however....

I want to take just the engine out, and leave the gearbox in the car, as I don't think my hoist will lift high enough to remove both as a unit from the engine bay in one go. My issue is trying to split the engine and gearbox at the bell housing. I have removed all the bolts, and wobbled the whole assembly to try and get them to split, but no joy. I have even put a bit of wood through the hole where the starter motor sits and banged with a mallet against the back of the bell housing.....

All this leads to me being stuck with the engine dangling from the hoist, and the gearbox refusing to come loose, and a big canvas covering the lot from the rain until I know what to do. The car had sat for several years before I have started to work on it, what are the chances it has rusted together a bit? What is the cure?

So, in brief:

1) Anyone else had this problem, and found a way round?

2) What about lifting the body off the chassis and away from the engine, making access easier? The body is a completely stripped shell with everything removed, and the 12 chassis to body bolts gone too. Can this be lifted with 4 blokes, (the glass is still in)?

I read a post on here about removing the engine being a three minute job, no such luck! If only I had an over-head beam so that I could use a block and tackle, then lifting height would be no issue.....

Chris

- bash

- Senior Poster

- Posts: 2388

- Joined: Thu Nov 03, 2005 15:34

- Model: Se, V8

- Colour: white

- Year: 1986

- Location: Doncaster

- Contact:

Having taken the engine out a couple of times I found that the height of the arm wasnt so much as of an issue, but the length of the arm was cos it needed that to clear the nose of the car. If yours reaches I would drain the oil from the gearbox and undo the gearbox mounting ( 4 easy bolts ) and take it out as a whole. Put a couple of bolts back in to the bellhousing tho. If you want to keep going, the bellhousing has probably siezed on the dowels and you may be able to force an old wood chisil in the join to help release it, slighty brutal but can work ( put some copperslip on the dowels when you put it back). Personally tho Id take the gearbox out as well. With the gearbox on the balance point seems to be by putting a strap thro the inlet manifold centre two cylinder pipes. I would get a second pair of hands to guide it out tho just to stop any possible paintwork dings.

Two things are infinite: the universe and human stupidity; and I'm not sure about the universe.

-

chris knowles

- Senior Poster

- Posts: 426

- Joined: Thu Dec 29, 2005 16:26

Oh, there are dowels..... that is where my problem probably is....

I'll explain in a bit more detail what I have done so far....

The engine hoist was the longest one I could buy, and when I assembled it and rolled it over to the car I could see there would be trouble! Mr car has no front bumper, light pods, or any radiator or ducting, but when the hoist touches the front of the shell the arm goes across the engine bay with the hook dangling over the cam belt, and not the middle of the engine (damn).

So, the arm on its longest (0.5 ton) setting is too short, so I repositioned the hoist to be at the side of the car next to the passenger wheel arch. Now when the arm goes across the engine bay the hook dangles over the middle of the inlet manifold (hurray). I guess lifting from the side is just as good as lifting from the front (I have convinced myself).

There is one steel strop looped around the rear carb manifold, and another steel strop looped around the front carb manifold, and they both meet at a shackle on the hoists own hook. Looking at how long the lifting arm is, and how high it goes at max lift, I can't see that it will lift the engine and gearbox clear of the body... only the engine.

The engine has had everything taken off to make room and increase access. The prop shaft has been removed, and the bolts I have removed from the gearbox are the 4 small nuts underneath that link the chassis crossmember to that rubber mount on the underneath of the gearbox. These bolts (in pairs) are crudely welded to a thin metal strip each side that stops them turning when you undo the nuts from below. Are these the same four you mention? Another earlier post mentions that the 4 bolts to remove are "high up", and these ones aren't really.

As for the paint, it really isn't an issue as the whole shell is to be resprayed.

So, what next? I have to get this engine out!

Chris

I'll explain in a bit more detail what I have done so far....

The engine hoist was the longest one I could buy, and when I assembled it and rolled it over to the car I could see there would be trouble! Mr car has no front bumper, light pods, or any radiator or ducting, but when the hoist touches the front of the shell the arm goes across the engine bay with the hook dangling over the cam belt, and not the middle of the engine (damn).

So, the arm on its longest (0.5 ton) setting is too short, so I repositioned the hoist to be at the side of the car next to the passenger wheel arch. Now when the arm goes across the engine bay the hook dangles over the middle of the inlet manifold (hurray). I guess lifting from the side is just as good as lifting from the front (I have convinced myself).

There is one steel strop looped around the rear carb manifold, and another steel strop looped around the front carb manifold, and they both meet at a shackle on the hoists own hook. Looking at how long the lifting arm is, and how high it goes at max lift, I can't see that it will lift the engine and gearbox clear of the body... only the engine.

The engine has had everything taken off to make room and increase access. The prop shaft has been removed, and the bolts I have removed from the gearbox are the 4 small nuts underneath that link the chassis crossmember to that rubber mount on the underneath of the gearbox. These bolts (in pairs) are crudely welded to a thin metal strip each side that stops them turning when you undo the nuts from below. Are these the same four you mention? Another earlier post mentions that the 4 bolts to remove are "high up", and these ones aren't really.

As for the paint, it really isn't an issue as the whole shell is to be resprayed.

So, what next? I have to get this engine out!

Chris

- robertverhey

- Senior Poster

- Posts: 788

- Joined: Tue Nov 01, 2005 10:54

- Year: 0

- Location: Sydney

- Contact:

Chris

I hate to add to our woes, but my recollection of getting the engine and g'box out in one unit is that the car actually needed to be raised off the ground to allow for clearance between gearbox and bulkhead on its way out (it needs to be tipped back quite steeply, see my gallery at http://members.optusnet.com.au/~robert.verhey/ ) . If you don't raise the car, the back of gearbox wil "catch" on the ground and the box will jam itself up against the bulkhead.

I would be inclined to think it best to use your lifter from the front of car, and maybe support your engine / gbox on a trolley jack and roll it forward until you can get the sling centeres above ports 2/3 of the inlet manifold (this should be possible with radiator and oil cooler removed. But you may need to bite the bullet and get a bigger lifter......

Regards

Robert

I hate to add to our woes, but my recollection of getting the engine and g'box out in one unit is that the car actually needed to be raised off the ground to allow for clearance between gearbox and bulkhead on its way out (it needs to be tipped back quite steeply, see my gallery at http://members.optusnet.com.au/~robert.verhey/ ) . If you don't raise the car, the back of gearbox wil "catch" on the ground and the box will jam itself up against the bulkhead.

I would be inclined to think it best to use your lifter from the front of car, and maybe support your engine / gbox on a trolley jack and roll it forward until you can get the sling centeres above ports 2/3 of the inlet manifold (this should be possible with radiator and oil cooler removed. But you may need to bite the bullet and get a bigger lifter......

Regards

Robert

Robert Glacier Blue '87 SE

-

chris knowles

- Senior Poster

- Posts: 426

- Joined: Thu Dec 29, 2005 16:26

Cheers for the help so far guys.

The car is up on axel stands at the moment, well above usual ride height. How high does it need to be for the gearbox to clear? Also, I think even if I roll the engine forward on a trolley jack, with the hoist at the front of the car, the arm will still be to short. I'll see if I can't pop home and take a picture, (that will speak a thousand words...).

I can crudely move the car about by lowering it onto dollies, and "skateboarding" it around the garden.

Did you need to seperate your engine and gearbox, or keep it together?

Chris

The car is up on axel stands at the moment, well above usual ride height. How high does it need to be for the gearbox to clear? Also, I think even if I roll the engine forward on a trolley jack, with the hoist at the front of the car, the arm will still be to short. I'll see if I can't pop home and take a picture, (that will speak a thousand words...).

I can crudely move the car about by lowering it onto dollies, and "skateboarding" it around the garden.

Did you need to seperate your engine and gearbox, or keep it together?

Chris

- robertverhey

- Senior Poster

- Posts: 788

- Joined: Tue Nov 01, 2005 10:54

- Year: 0

- Location: Sydney

- Contact:

The very last pic in the panel of four shows how much daylight under the front wheel. That was enough.

I was replacing rear engine oil seal and clutch so yes, had to split them apart. But can't recall any dramas once the bots were removed, just prised them apart with a couple of screwdrivers....

Robert

I was replacing rear engine oil seal and clutch so yes, had to split them apart. But can't recall any dramas once the bots were removed, just prised them apart with a couple of screwdrivers....

Robert

Robert Glacier Blue '87 SE

-

chris knowles

- Senior Poster

- Posts: 426

- Joined: Thu Dec 29, 2005 16:26

Hi Guys,

Well, here are some images of the problem in hand. Remember, this blue Excel is my donor car which I bought for the body really. I have spent the last couple of months stripping a complete car down to this, so I can start installing my good running gear of my existing Excel... (and I am knackered....)

The body is on axel stands, the tires underneath are just there in case the worst happens. There are also two dolleys underneath, so I can lower the car and wheel it about. The chassis is not attached to the body, gravity alone is holding them together, (that and the gear stick poking up through the hole in the transmission tunnel).

Spav, how about a new bit on the website, "Most Desperate Restoration"?

Chris

Well, here are some images of the problem in hand. Remember, this blue Excel is my donor car which I bought for the body really. I have spent the last couple of months stripping a complete car down to this, so I can start installing my good running gear of my existing Excel... (and I am knackered....)

The body is on axel stands, the tires underneath are just there in case the worst happens. There are also two dolleys underneath, so I can lower the car and wheel it about. The chassis is not attached to the body, gravity alone is holding them together, (that and the gear stick poking up through the hole in the transmission tunnel).

Spav, how about a new bit on the website, "Most Desperate Restoration"?

Chris

My crane has a long reach, but I had the car up too high, and the straps not tight enough around the inlets, so it wouldn't lift the box clear, had to rest the engine box on the wings!!! with wood spreaders and carpets, and reposition the straps, it didn't cause any damage.

If you can get the box close enough, cover the wings, add some 2 by 4 planks under the box while standing in the bay and lifting the box, then slide the crane away, the box should follow, then you can twist the gearbox end clear.

Try dropping the front end down on a jack without the wheels.

From your photo, you've got the crane tip too far above the inlets, they should be nearly touching the hook, plus loose the chain. You don't need steel cable, strong nylon rope wrapped round the inlets evenly holds.

You will struggle from the side.

If you can get the box close enough, cover the wings, add some 2 by 4 planks under the box while standing in the bay and lifting the box, then slide the crane away, the box should follow, then you can twist the gearbox end clear.

Try dropping the front end down on a jack without the wheels.

From your photo, you've got the crane tip too far above the inlets, they should be nearly touching the hook, plus loose the chain. You don't need steel cable, strong nylon rope wrapped round the inlets evenly holds.

You will struggle from the side.

If its a sealy SC10 crane i purchased one to do the clutch on mine.Anyway turn out the jib wasnt long enough ,anyway i just happened to have a lengh of T angle in the garden been there for years made up an extension and it come out fine.

BUT have u taken out the bolt thats hidden under thes starter ?i was trying to split them just as u are includeing chisel / screwdriver and a hammer to split them ,only to find this last bolt took it out and they came apart no problem .A bit akward to get at from the top

BUT have u taken out the bolt thats hidden under thes starter ?i was trying to split them just as u are includeing chisel / screwdriver and a hammer to split them ,only to find this last bolt took it out and they came apart no problem .A bit akward to get at from the top

-

Skeggy

- Senior Poster

- Posts: 434

- Joined: Mon May 01, 2006 18:09

- Year: 0

- Location: Skegness, England

- Contact:

Chris,

I've never taken an engine out with a crane from the wing side. Just think about the lift angle and you'll see that the engine is going to be lifted sideways.

I agree with all the others that the problem is likely to be the dowels but if you had the crane at the front you can pull (yank!) on the crane to seperate the engine from the gearbox.

If the crane arm is to short then use longer links from the crane to the engine and when you get it halfway out support engine and shorten links.

Let us all know how you get on.

I've never taken an engine out with a crane from the wing side. Just think about the lift angle and you'll see that the engine is going to be lifted sideways.

I agree with all the others that the problem is likely to be the dowels but if you had the crane at the front you can pull (yank!) on the crane to seperate the engine from the gearbox.

If the crane arm is to short then use longer links from the crane to the engine and when you get it halfway out support engine and shorten links.

Let us all know how you get on.

Some of them are just driving a racing car but some are racing drivers.

-

chris knowles

- Senior Poster

- Posts: 426

- Joined: Thu Dec 29, 2005 16:26

Hi guys,

I only had a short while to do some more last night before the light started to fail. I spent most of the time removing the cross member from the gearbox, (the one with the large rubber part), as now it seems I am taking the 'box out too. The bolts for this where well on indeed!

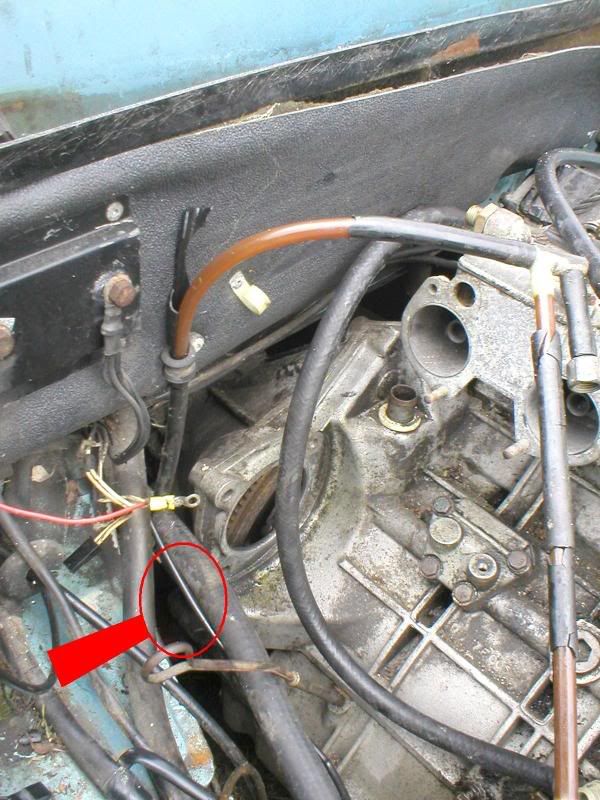

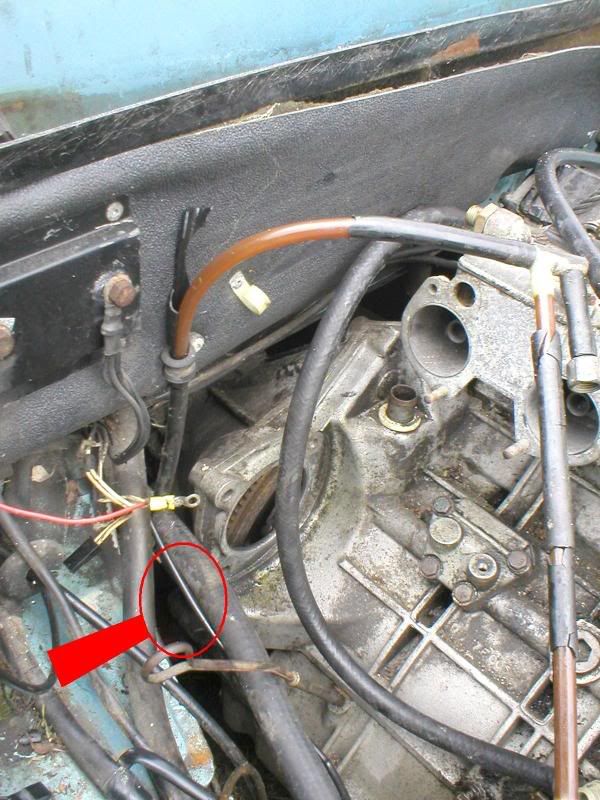

That mystery bolt under the starter, is it this one?

I read your point about the possibility of missing a bolt this morning, and I am desperate to go back and check that this is why my bell housing won't come off! I am pretty sure I have removed them all, though.

The final plan is to get the engine/box to the front of the engine bay with the hoist where it is, support it, move the hoist from the side to the front of the car and then lift again for the final extraction. If I have to make a slightly longer arm out of some box section then so be it.

Out of interest, the cable drive from the gearbox, how do you remove it? I have taken out the bolt and the plate that seem to hold it in place, but it was too dark to see what to do next, and I didn't want to just yank it out. Is there a trick to removing it?

Chris

I only had a short while to do some more last night before the light started to fail. I spent most of the time removing the cross member from the gearbox, (the one with the large rubber part), as now it seems I am taking the 'box out too. The bolts for this where well on indeed!

That mystery bolt under the starter, is it this one?

I read your point about the possibility of missing a bolt this morning, and I am desperate to go back and check that this is why my bell housing won't come off! I am pretty sure I have removed them all, though.

The final plan is to get the engine/box to the front of the engine bay with the hoist where it is, support it, move the hoist from the side to the front of the car and then lift again for the final extraction. If I have to make a slightly longer arm out of some box section then so be it.

Out of interest, the cable drive from the gearbox, how do you remove it? I have taken out the bolt and the plate that seem to hold it in place, but it was too dark to see what to do next, and I didn't want to just yank it out. Is there a trick to removing it?

Chris

- GavinTaylor

- Regular Poster

- Posts: 128

- Joined: Tue Nov 01, 2005 05:59

- Model: Excel

- Colour: Saturn Red

- Year: 1984

- Location: Melbourne, Oz

Chris,

My opinion:

Yes, get a longer piece of square section steel tube to replace the black piece.

Move the hoist to the front and stick the new square section through the top loops of the slings.

I'd forget trying to take out the engine/gearbox as a unit. You're going to need a lot of height to do that.

I too, just don't believe they won't separate with a screwdriver and some serious wriggling, rusty dowels, or no.

Oh, yeah . . . you're going to fix the lawn, I hope!

Gavin

My opinion:

Yes, get a longer piece of square section steel tube to replace the black piece.

Move the hoist to the front and stick the new square section through the top loops of the slings.

I'd forget trying to take out the engine/gearbox as a unit. You're going to need a lot of height to do that.

I too, just don't believe they won't separate with a screwdriver and some serious wriggling, rusty dowels, or no.

Oh, yeah . . . you're going to fix the lawn, I hope!

Gavin

- robertverhey

- Senior Poster

- Posts: 788

- Joined: Tue Nov 01, 2005 10:54

- Year: 0

- Location: Sydney

- Contact:

-

chris knowles

- Senior Poster

- Posts: 426

- Joined: Thu Dec 29, 2005 16:26

Oh, it's never easy, is it? You can all enjoy my struggle this week in pictures anyway, so there is something to look forward to.....

Gavin, I am confused as to what your second to last sentence means? Do you think I can or cannot separate them with some furious chisel action?

As for the lawn... wait for it...... that is my parents garden! I live 2 minutes away, but my garage only fits one car, (my other Excel), with my normal car using the drive space. That and my partner would do her nut if there where two Excels at the house. My dear old mum and dad were kind enough to lend me a spot down the end of the garden, where the neighbours can't see......

Are you suggesting old petrol, oil, transmission/power steering goo, and brake fluid are not good for a healthy looking lawn?

Chris

Gavin, I am confused as to what your second to last sentence means? Do you think I can or cannot separate them with some furious chisel action?

As for the lawn... wait for it...... that is my parents garden! I live 2 minutes away, but my garage only fits one car, (my other Excel), with my normal car using the drive space. That and my partner would do her nut if there where two Excels at the house. My dear old mum and dad were kind enough to lend me a spot down the end of the garden, where the neighbours can't see......

Are you suggesting old petrol, oil, transmission/power steering goo, and brake fluid are not good for a healthy looking lawn?

Chris

- GavinTaylor

- Regular Poster

- Posts: 128

- Joined: Tue Nov 01, 2005 05:59

- Model: Excel

- Colour: Saturn Red

- Year: 1984

- Location: Melbourne, Oz

I'm saying the engine and gearbox will separate - absolutely.chris knowles wrote:Gavin, I am confused as to what your second to last sentence means? Do you think I can or cannot separate them with some furious chisel action?

In any other engine-out operation I've done, the engine and gearbox will at least start to separate while you are taking out the bolts.

I confess, I can't really see that bolt, but it may well be there as Robert says. That could also be enough to stop any separation taking place as would usually happen.

Here's something . . . firstly ensure all bolts are removed. Place a jack under the rear end of the gearbox and lift. That may well break it free.

Gavin